Quickfit Panels

The construction of the FCS Quickfit Panel makes them ideally suited to replace existing roofs or for incorporating in new heater construction.

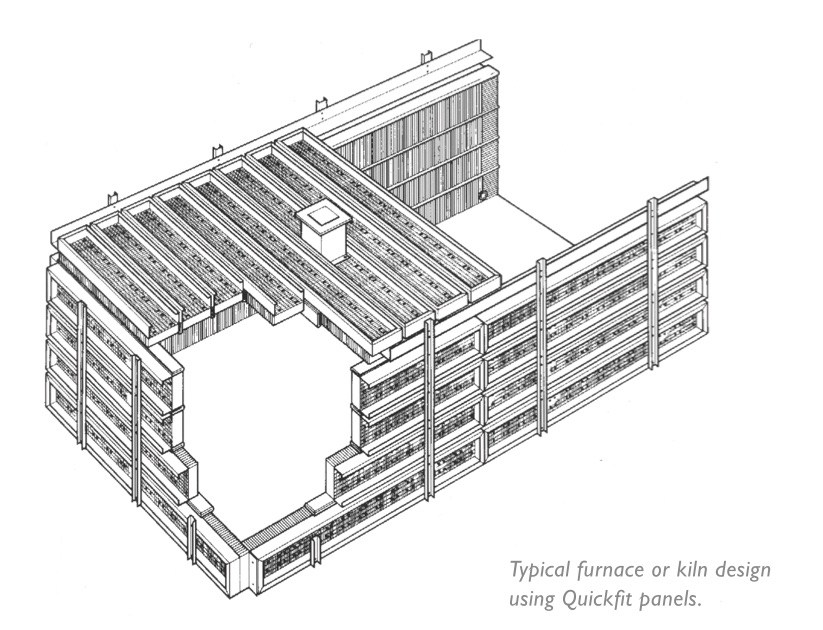

Quickfit Panels may be bolted together to form large areas of roof, sidewalls and doors, or used individually on smaller installations. The method of construction from stock items allows for speedy delivery to the customer.

The panels consists of ceramic fibre blanket folded to give a dense module suspended on high temperature anchors, which are secreted back from the panel hot face. The fibre is slung from a mild steel open metalwork mat. The whole structure is surrounded by a mild steel skirt which is welded to the open metalwork mat.

DESIGN ADVANTAGES

The corrugation bends present the ceramic fibres at right angles to the heat source giving better insulation properties than stacked fibres

Insulation density is 9lbs./cubic foot min

The mechanical fixing of the fibre caters for situations of heavy vibration

Temperature shrinkage of the fibres in any direction is catered for during assembly

Roof panels may be of any span but the width is limited to 2 feet. Larger areas are covered by bolt-together type panels

Mechanically damaged panels can be repaired in situ by quick replacement of separate blocks which make up the panel

The absence of continuous steel outer surfaces eliminates dewpoint problems

The open metal construction is strong, lightweight and non-distorting giving these following advantages:

Quick and simple replacement

Hot spots, should they occur, are immediately noticeable and temporary repairs can be carried out with the plant still producing

Atmosphere analysis and temperature sampling can be easily undertaken in any position through the panel

Request a call back